wine bottles spraying

Carbon fiber sporting goods spraying

Burglarproof door industry spraying

Door and window accessories spraying

Home appliance / kitchenware spraying

Auto parts spraying

Construction machinery spraying

Wood products, furniture spraying

Plating,protection,etc spraying

Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: No,55 Xinghe Road. Xiabian industrial. Chanan town. dongguan China

Hotline:86-13926859125

automotive and domestically used goods.

glass wine bottle coating painting system that provides high-performance efficiency, safety, quality coating.

HDA -60 electrostatic rotating bell spray gun

| aomization | centrifugal force ofturbine motor | driving form | air bearing turbine |

| Bell dimension | Φ20mm, Φ30mm, Φ50mm, Φ65mm | spray width | 100-500mm |

| Max output voltage | DC-20-80KV | max output current | 300ua |

| Max flow rate | 500cc/min | Max speed | 70000rpm/min ( un-load |

| Max air consumption | 1.0Nm3/min | length | 600mm reciprocation machine |

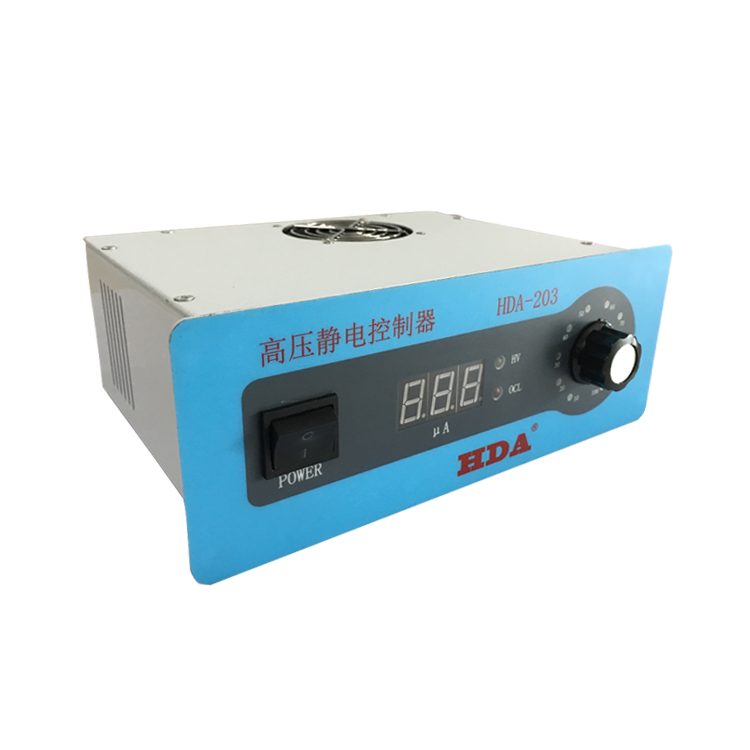

| Weigh | 5.5kgs | electrostatic controller | HAD-201 |

| Installation method | Fixed, reciprocation machine ro coating robot |

Roatry bell generally has three installation methods: fixed, reciprocation machine, robot, paintfrom the center to the high speed rotating bell head, bell head is charged and 80KV high voltage transmission to the paint, when the paint touches the bell head. is charged with high voltage negativ charge, because thsescharges reple each other, when the paint leaves the bell head, paint particles it's split by the charge into smaller and nore uniform particles until the surface thnsion of the coating is balanced with the charge repulsion

|

high voltage |

DC-80KV |

|

|

high voltage adjustment |

15KV-80KV Unsection type |

|

|

high voltage switch |

Automatic & Manual |

|

|

supply voltage |

AC110V-240V 50/60HZ |

The combination of electrostatic effect and hgh sped rotating centrifugal force producesbetter and more uniform coating particles, the high voltage charged particles are attracted to wellground ded workpicees, resulting in excellent surface quality and high coating transfer efficiency