- wine bottles spraying

- Carbon fiber sporting goo

- Burglarproof door industr

- Door and window accessori

- Home appliance / kitchenw

- Auto parts spraying

- Construction machinery sp

- Wood products, furniture

- Plating,protection,etc sp

Glass bottle coating, glass packing bottle coating

2022.08.15

The era of industry 4.0 surfaces coating get new and specific tasks, but it is possible only with the development

of electrostatic spraying particulate pigments.These new modern coatings are multifunctional

and digitize the paint & ink manufacturer to other basic principles.

Liquid electrostatic Coating is a process during which a metal part is covered with high-quality,

durable finish with improved efficiencies and simplified environmental compliance. Unlike conventional

liquid paint which is delivered via an evaporating solvent, liquid paint coating is typically applied electrostatically

and then cured under heat. This coating method is common for many markets, including industrial production,

automotive and domestically used goods.

ones, add a component of remote connectivity via cellular 4G LTE. New or legacy systems can be upgraded with Industrial

Cellular Routers or Gateways to be connected to the automated control units. These devices provide secure and uninterrupted

connectivity channel between the system, the manufacturer of the system and system operators, such as production, service,

quality and/or process managers with the help of dedicated IoT Platform as a user interface.

HDA automatic spray system is an auto body Automobile industry, Automobile parts, new energy accessories, shells, wheels, helmets and other plastic and metal parts.

2. machinery coating: Switchboard, control panel, air conditioning machine, OA machine, household appliances, construction machine, grinding machine, production line coating.

3. building materials, furniture: office machinery, steel furniture, doors and windows spraying, materials bars, Aluminum bars spraying,

4.hardwares spraying: Luggage hardware accessories, decoration hardware, jewelry parts UV coating.

5.Glass bottle coating, glass packing bottle coating, perfume bottle coating, glass cosmetics bottle and

glass wine bottle coating painting system that provides high-performance efficiency, safety, quality coating.

HDA -60 electrostatic rotating bell spray gun

Air turbine bell electrostatic spray gun

| aomization | centrifugal force ofturbine motor | driving form | air bearing turbine |

| Bell dimension | Φ20mm, Φ30mm, Φ50mm, Φ65mm | spray width | 100-500mm |

| Max output voltage | DC-20-80KV | max output current | 300ua |

| Max flow rate | 500cc/min | Max speed | 70000rpm/min ( un-load |

| Max air consumption | 1.0Nm3/min | length | 600mm reciprocation machine |

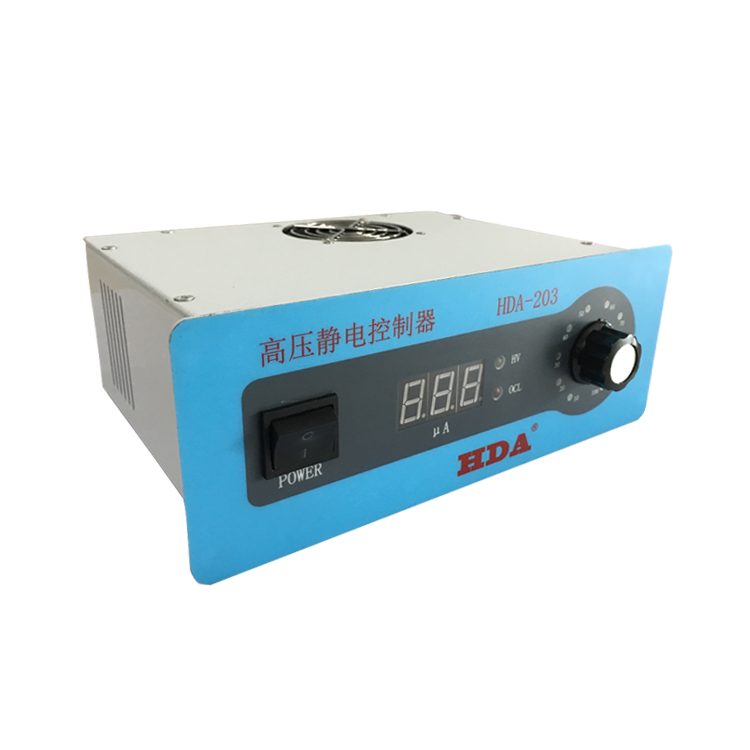

| Weigh | 5.5kgs | electrostatic controller | HAD-201 |

| Installation method | Fixed, reciprocation machine ro coating robot |

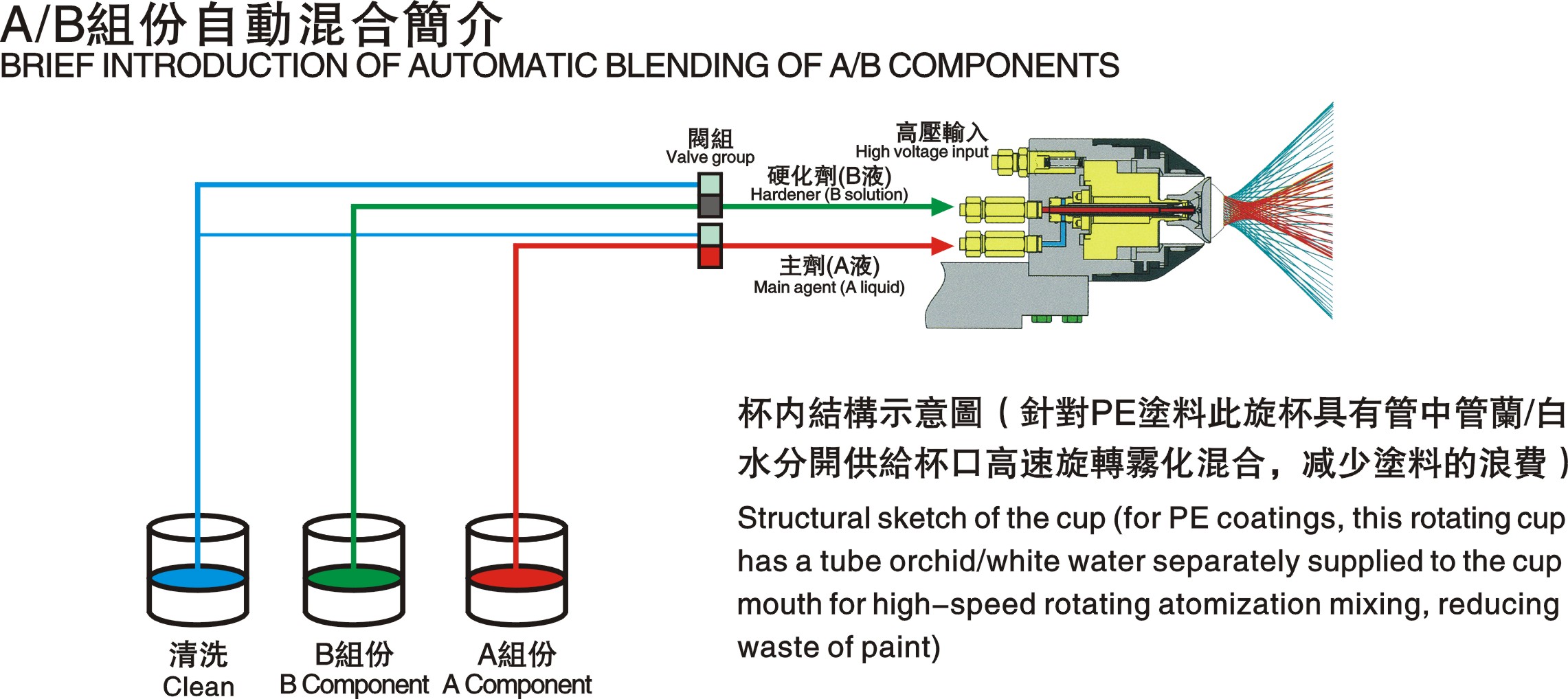

Roatry bell generally has three installation methods: fixed, reciprocation machine, robot, paintfrom the center to the high speed rotating bell head, bell head is charged and 80KV high voltage transmission to the paint, when the paint touches the bell head. is charged with high voltage negativ charge, because thsescharges reple each other, when the paint leaves the bell head, paint particles it's split by the charge into smaller and nore uniform particles until the surface thnsion of the coating is balanced with the charge repulsion

|

high voltage |

DC-80KV |

|

|

high voltage adjustment |

15KV-80KV Unsection type |

|

|

high voltage switch |

Automatic & Manual |

|

|

supply voltage |

AC110V-240V 50/60HZ |

The combination of electrostatic effect and hgh sped rotating centrifugal force producesbetter and more uniform coating particles, the high voltage charged particles are attracted to wellground ded workpicees, resulting in excellent surface quality and high coating transfer efficiency

Previous:Dust Free Electrostatic rotating bell for glass bottle coating

Next:HDA Electrostatic bell metal wood parts coating

BACK

BACK HDA HOME

HDA HOME Navbar

Navbar

Other Project

Other Project