Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: Block A No336, Changqing North Road Chanan Town . dongguan China

Hotline:86-13926859125

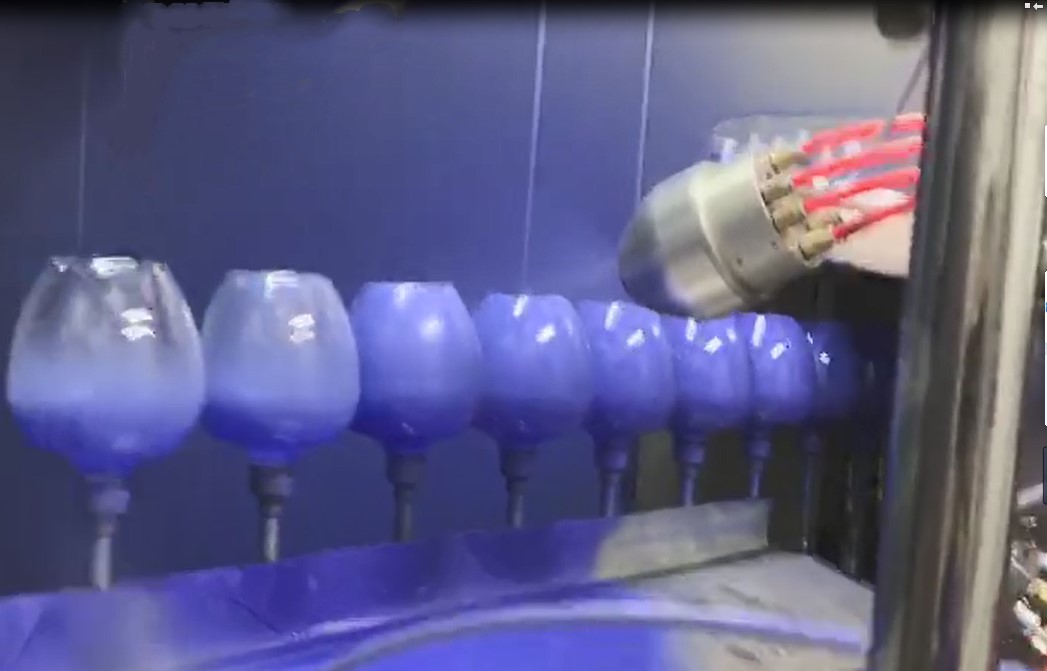

A rotary atomizer is an automatic electrostatic paint applicator used in high volume, automatic production painting environments. Also called a 'paint bell', "rotary bell atomizer" or 'bell applicator', it is preferred for high volume paint application for its superior transfer efficiency, spray pattern consistency, and low compressed air consumption, when compared to a paint spray gun. It can be mounted in a fixed position, reciprocating arm, or an industrial robot.

the current trend in automotive finishing industry is to use more electrostatic rotating bell spray system, need space to their higher transfer efficiency. The flow physics related with the transfer efficiency is strongly influenced by operating parameters.

In order to improve their high transfer efficiency without compromising the coating quality,

a better understanding is necessary to the HDA electrostatic automatic rotating bell application of metallic base coat painting for the automobile exterior. This paper presents the results from experimental investigation of the HDA electrostatic spray to apply electrostatic liquid paint painting.

1.glass wine bottle UV spraying

Spray Coating On Glass Bottles Using Uv Lacquer Spray coating with UV lacquer could bring glass bottle makers closer to the ideal manufacturing capability of handling lot sizes of one with no changeover time - provided that the adhesion of the lacquer is lasting and the coatings do not deteriorate during the lifetime of the bottles.

UV protection helps in maintaining the quality of light-sensitive products, thereby prolonging their effectiveness and their shelf life. Products that are sensitive to light include food items, medicines, beer and wine, and milk. Some beauty products are also sensitive and can lose their effectiveness when left unprotected.

in order to enhance the artistic appeal of the glass bottle, color is sprayed on the glass bottle according to relevant requirements

With the change of life, innovation has always been a hot topic for people. Innovation is needed in any industry, and glass bottles are no exception. Now there are many glass wine bottles with different shapes on the market, which better shows that glass bottle modeling design is a space art, which uses a variety of different materials and processing means to create three-dimensional images in space.

The spraying production line is generally composed of spraying booth,

Spindle coating Line and oven. There is also the previous water treatment for glass bottles is important. What glass bottles need to pay special attention to is sewage discharge. As for the quality of spraying, it is related to water treatment, surface cleaning of work pieces, conductivity of fixture, air pressure, the spray quality, depend on the level of operators. The following methods are recommended:

1. Pretreatment section. The pretreatment section includes pre stripping, main stripping, surface conditioning, etc. if it is in the north, the temperature of the main stripping part cannot be too low, and it needs heat preservation. Otherwise, the treatment effect is not ideal;

2. Preheating section. After pretreatment, it will enter the preheating section, which generally takes 8-10 minutes. When the glass bottle arrives at the spray booth, it should make the sprayed workpiece have a certain amount of waste heat to increase the adhesion of the paint;

3. Soot blowing purification section. If the process requirements of the sprayed workpiece are relatively high, this section is essential, otherwise if there is a lot of dust adsorbed on the workpiece, there will be a lot of particles on the surface of the processed workpiece, which will reduce the quality;

4. Painting section. The key of this section is the technical problem of the spraying workers. In order to create good quality, we need skilled and professional work to operate.

5. Drying section. In this section, we should pay attention to the temperature and baking time. Generally, 180-200 degrees is better, depending on the material of the workpiece. In addition, the drying furnace should not be too far from the spraying room, generally 6 meters is good.

When determining the basic shape of a glass bottle, the "sculpture method" is often used as the basic segment, and then the shape is cut or combined. The positioning of the basic shape comes from the geometric shape, such as sphere, cube, cylinder, cone, etc. The basic shape of cosmetic bottle is usually a cylinder, and the cylindrical structure in three-dimensional composition is mainly reflected in three aspects: the change of the end of the cylinder, the change of the cylinder and the change of the prism of the cylinder, which adopts the methods of cutting, bending, rotating, concave and so on. It makes the designed glass bottles strange, and correspondingly, these glass bottles with changing shapes make people's enthusiasm for the glass bottle industry never fade!

DONGGUAN HONGDA SPRAYING ELECTROMECHANCAL CO.,LTD

Factory: No,55 Xinghe Road. Xiabian industrial. Chanan town. dongguan China

Contact person: Ms Croesus

Phone: 86 13622624429 (same as wechat)

E-mail:hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com