Manual electrostatic spray gun

Automatic electrostatic spray gun

Water paint electrostatic spray gun

Electrostatic spray gun accessories

pumps

Electrostatic spray gun parts

Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: No,55 Xinghe Road. Xiabian industrial. Chanan town. dongguan China

Hotline:86-13926859125

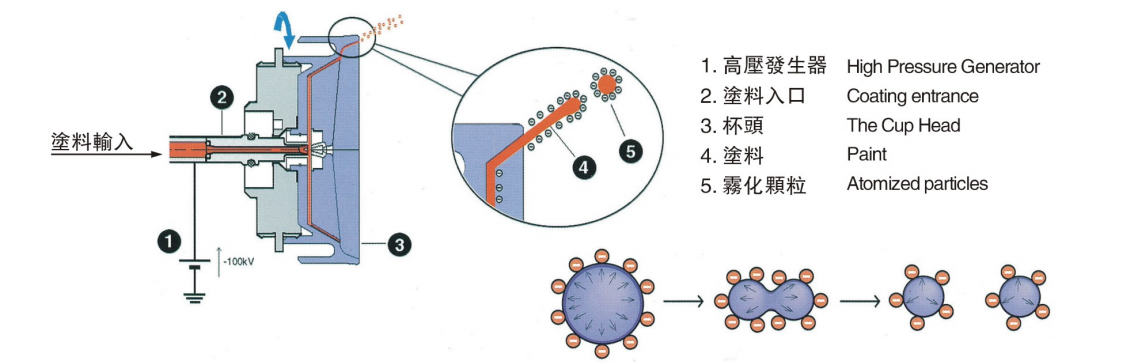

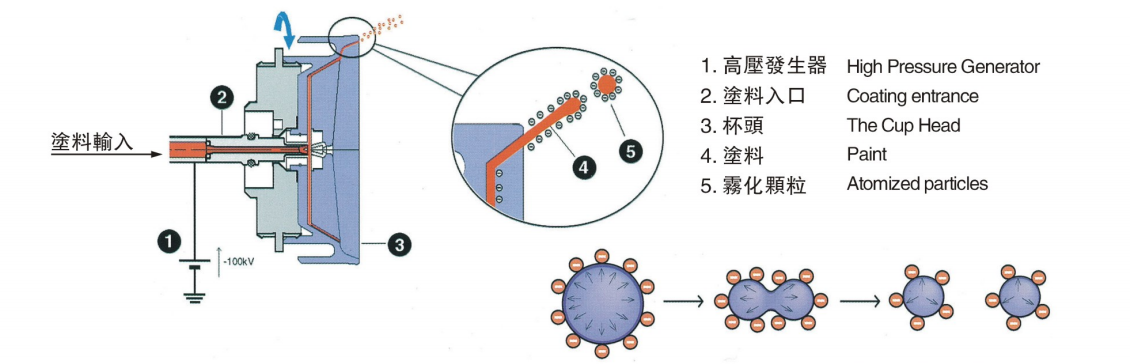

Working principle of electrostatic rotating cup

The coating is delivered from the center to the high-speed rotating cup head, which is charged and transmits a high voltage of 80 kV to the coating. When the coating comes into contact with the cup head, it is charged with a high voltage negative charge, because these charges repel each other.

When the paint leaves the cup head, the paint particles are divided into smaller and more uniform particles by the charge until the surface tension of the paint is in equilibrium with the charge repulsion. Electrostatic force acting on the centrifugal force of high speed rotation,

The resulting better, more uniform coating particles, which are highly charged, are attracted to well-grounded workpieces, resulting in excellent surface quality and extremely high coating transfer efficiency.

| aomization | centrifugal force ofturbine motor | driving form | air bearing turbine |

| Bell dimension | Φ20mm, Φ30mm, Φ50mm, Φ65mm | spray width | 100-500mm |

| Max output voltage | DC-20-80KV | max output current | 300ua |

| Max flow rate | 500cc/min | Max speed | 70000rpm/min ( un-load |

| Max air consumption | 1.0Nm3/min | length | 600mm reciprocation machine |

| Weigh | 5.5kgs | electrostatic controller | HAD-201 |

| Installation method | Fixed, reciprocation machine ro coating robot |

Electrostatic action combined with high-speed rotating centrifugal force produces better and more uniform coating particles, which are attracted to well-grounded workpieces, resulting in excellent surface quality and extremely high coating transfer efficiency.

Features and Applications of Spraying

Static electricity spraying is the principle of electrostatic spraying, the use of electrostatic spray on the coating of electrostatic pressure atomization technology, improve the overall adhesion ability of the product surface coating, as well as the performance and life of the coating. In the past, the traditional paint waste is large and the production efficiency is low. The electrostatic rotating cup atomizes the paint by using high speed to reduce the paint waste in spraying, and the effect of electrostatic coating surface is better.

HDA spray gn - Electrostatic rotating bell HDA-60

Under load, the maximum speed of the rotating cup can reach 80000 / min.

The atomization bell cup (for PE liquid paint, and it has high speed of separating. the tube's Orchid water supply to the atomizing bell cup mouthrotary atomizing mixtre to reduce paint waste.

The automatic electrostatic rotating bell spray guns applications:

1. Automobile spraying: auto parts, lager metal parts, container body, and any plastic components manual coating.

2. Machinery spraying: metal machinery cage, OA machinery, control panel, condition machine, household spraying.

3. Raw materials spraying: furniture wood parts, steel door and windows, metal bar, Aluminum bar spraying,construction materials spraying.

4.others:hardware coating,painting and wooden products coating;

5.Glass bottle coating, glass perfume bottle coating, glass cosmetics bottle and glass wine bottle coating

DONGGUAN HONGDA SPRAYING ELECTROMECHANCAL CO.,LTD

Factory: No,55 Xinghe Road. Xiabian industrial. Chanan town. dongguan China

Contact person: Ms Croesus

Phone: 86 13622624429 (same as wechat)

E-mail:hda-sl01@hongdapt.com