Manual electrostatic spray gun

Automatic electrostatic spray gun

Water paint electrostatic spray gun

Electrostatic spray gun accessories

pumps

Electrostatic spray gun parts

Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: Block A No336, Changqing North Road Chanan Town . dongguan China

Hotline:+86-13622624429

Industrial spray gun HDA electrostatic paint spray equipment

Automatic static rotating bell spray gun have multiple advantages

·Efficient painting: The automatic electrostatic rotating bell spray gun can achieve automated intelligent control, simplify the structure, achieve efficient painting, and greatly improve production efficiency .

·Cost saving: Through electrostatic adsorption properties, the utilization rate of pigments is significantly improved, thereby saving a large amount of coating costs. At the same time, automated operations reduce human intervention and further reduce costs.

·High-quality coating: high spray uniformity, effectively avoids the problem of coating thickness and unevenness, significantly improves coating quality 2. Environmental protection and energy saving: reduces solvent and air consumption, reduces VOC emissions, and is conducive to environmental protection .

Automatic electrostatic cylinder spray guns occupy an important position in the spraying industry due to their advantages of efficiency, economy, quality and environmental protection.

HDA-605 electrostatic rotating bell spray gun

|

Item Name |

Parameters |

|

|

Flotation pressure |

0.4-0.8 MPa |

|

|

Speed pressure |

0.1MPa 33000-36000rpm |

|

|

0.15MPa 40000-45000rpm |

|

|

|

0.15MPa 40000-45000rpm |

|

|

|

0.25MPa 55000-6000rpm |

|

|

|

atomization tip |

1.0MM (Optional) |

|

|

|

1.5MM (Optional) |

|

|

|

2.0 MM (standard) |

|

|

Spray width air pressure |

0.15-0.4 MPa |

|

|

Bell cup dimensions |

Φ30mm atomization tip |

Φ40-50mm |

|

Φ50mm atomization tip |

Φ60-100mm |

|

|

Φ60mm atomization tip |

Φ200-300mm |

|

|

Rotating speed |

400-450L/min |

|

|

Spray width |

|

|

HDA-203 Electrostatic controller:

|

Output adjustment |

DC-20-60KV |

|

voltage |

AC24V |

|

Maximum current |

80uA |

|

supply voltage |

AC220V±10% |

|

dimensions |

260X160X350mm |

|

application environment |

temperature 0-45℃ |

|

dampness 20-85℃ |

The electrostatic controller of the electrostatic spray gun is the key component of the electrostatic spray gun system. It is responsible for generating the electrostatic field force, making the coating particles negatively charged and effectively adsorbed on the surface of the coating. The following is a detailed description of the electrostatic device of the electric spray gun:

· Function: The static controller generates static electric field forces to negatively charge the coating particles, thereby enhancing the coating's adsorption effect on the painted substance and improving the painting efficiency and quality.

· Type: According to the type of electrostatic spray gun, electrostatic controller can be divided into manual electrostatic spray gun controller and automatic electrostatic spray gun controller. Manual controllers are suitable for the spraying of large, medium and small workpieces, while automatic controllers are mostly used to automate production lines.

Application: Static electricity controller is widely used in hardware, carbon fiber, wood, plating protection and other industries. It is suitable for static electricity spraying of liquid, paint, powder, waterborne paint and so on.

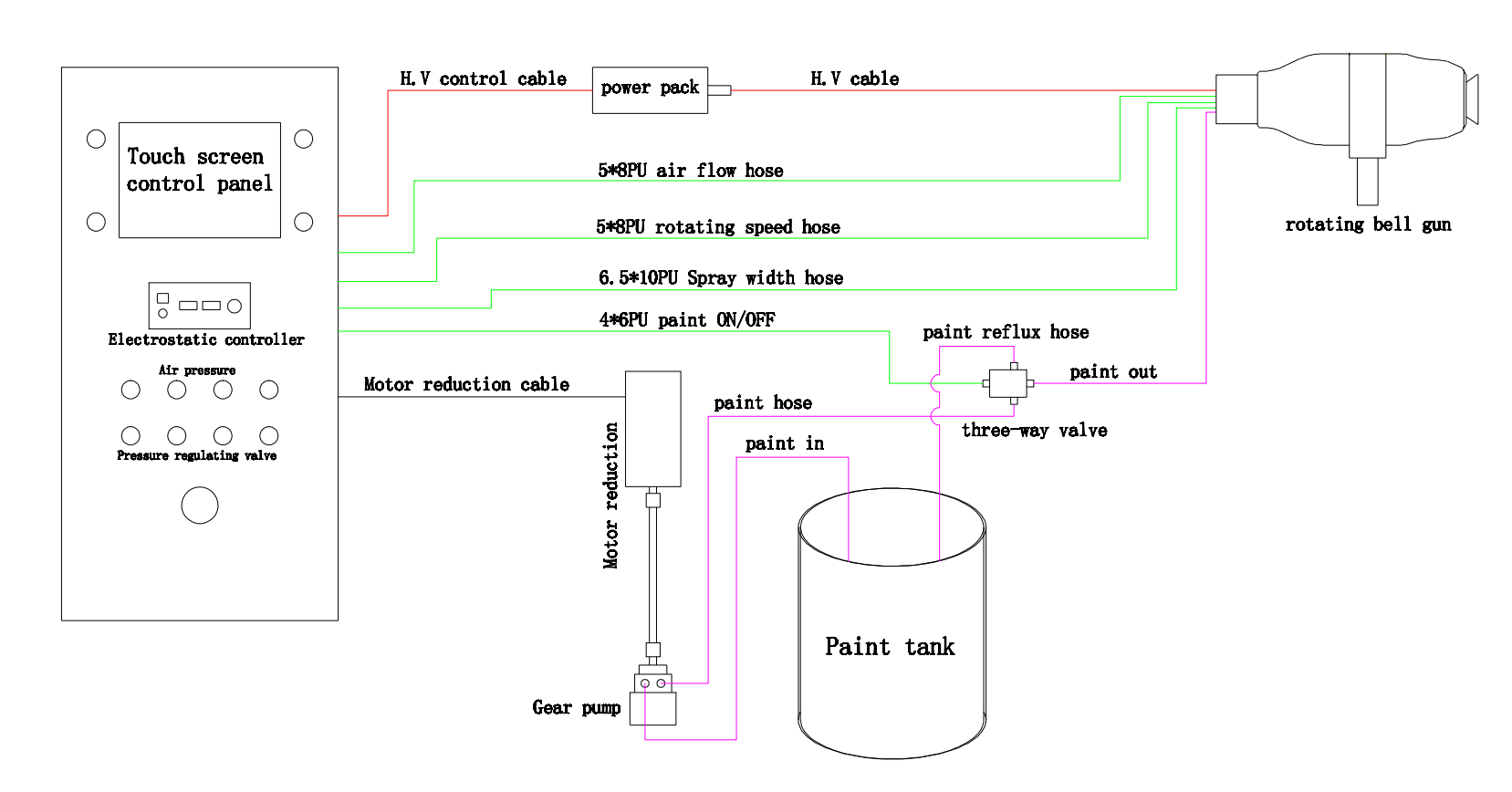

Electrostatic rotating bell system:

|

|

Automatic electrostatic rotary cup spraying gun PLC control cabinet is a special automatic control equipment for spraying process. Here's a detailed answer about the device:

Main composition: PLC (main machine), HMI (display screen), electric components.

Working principle: Through electromagnetically operated valve, electrical proportional valve, relay and other electronic and electrical components for remote control, PLC logic editing, HMI screen display, centralized spraying process control. · Functional Features:

· The program can be designed according to the production process needs, enabling customized program logic editing of spray parameters, simple and convenient, and centralized management.

· A variety of customized requirements such as point spraying, flash spraying, variable spraying, one-click color change can be implemented.

· External control can be connected to enable interconnection with multi-axis machines or robots, and network transformation intelligent end displays can be customized.