Manual electrostatic spray gun

Automatic electrostatic spray gun

Water paint electrostatic spray gun

Electrostatic spray gun accessories

pumps

Electrostatic spray gun parts

Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: No,55 Xinghe Road. Xiabian industrial. Chanan town. dongguan China

Hotline:86-13926859125

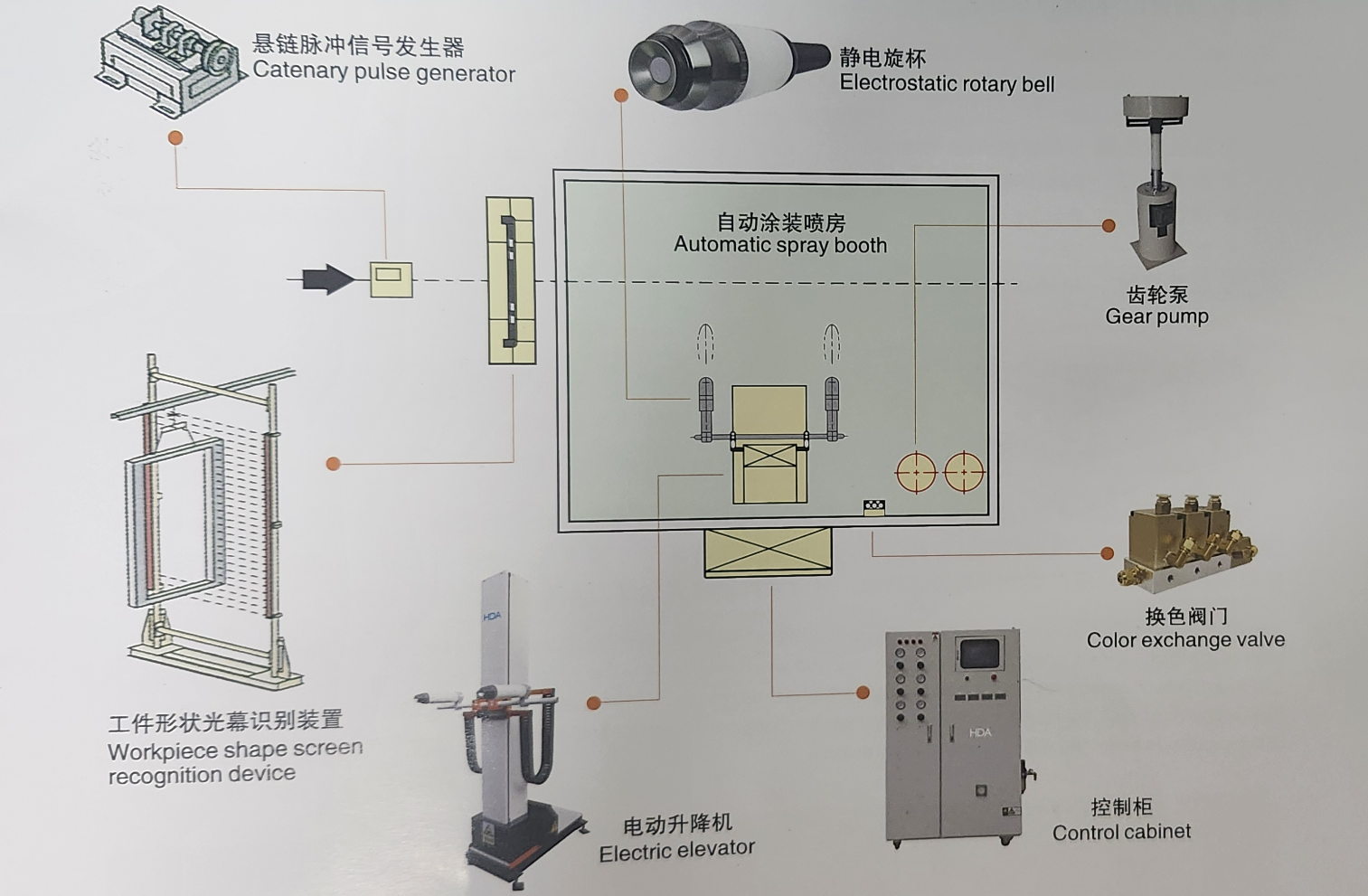

Function description:

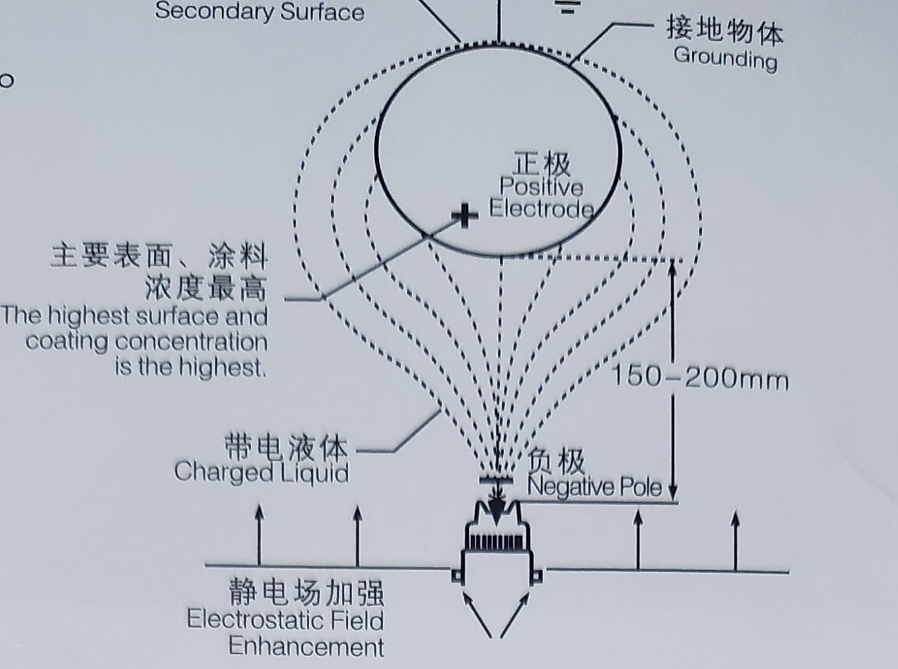

Under the action of centrifugal force of high-speed rotation of the,

Rotating bellthe coating will be separated from thebell through the

small teeth around the rotary cup into fibrous filaments. Under the action

of centrifugal force and high electric charge, the coating will be micronized and evenly distributed in the spray space. The coating can be effectively adsorbed on the workpiece with positive charge by carrying high voltage negative charge. The coating efficiency is greatly improved, the coating is even, and the gloss of the coating film is enhanced.

|

Amortization |

ofturbine motor | driving form | air bearing turbine |

| Bell dimension | Φ30mm, Φ50mm, Φ65 | spray width | 100-500mm |

| Max output voltage | DC-20-80KV | max output current | 300ua |

| Max flow rate | 500cc/min | Max speed | 100000rpm/min ( un-load |

| Max air consumption | 1.0Nm3/min | length | 600mm reciprocation machine |

| Weigh | 5.5kgs | electrostatic controller | HAD-203 |

| Installation method | Fixed, reciprocation machine ro coating robot |

| outup ajustment | DC-20-60KV | |

| voltage | AC24V | |

| Maximum current | 80uA | |

| supply voltage | AC220V±10% | |

| Dimention | 260X160X350mm | |

| application environment | temperature 0-45℃ | |

| dampness 20-85℃ | ||

|

Electrostatic spraying is accomplished by applying high voltage electrostatic charge on the coating particles to the coating parts with good grounding, the advantage of electrostatic spraying is to improve the efficiency of coating transmission and refuce the waste of paint electrostatic spraying technology is usually used by factories with large production volume and high quality requirements so as to save production costs. |

|

|

Advantages of electrostatic spraying: Excellent surface quality: Coatings are further atomized by applying static charges, resulting un better surface qualituy with smaller coating particles. Increase productivity: Each storke allows more workpiece surfaces to be sprayed, therby improving the efficiency of the spray. Save paint: The environmental effect of static electricity and uniform spraying interface make more paint sprayed to the surfae of the workpiece, the result is not only better surface quality, but also save 35-50% of the paint. Reduce the maintenance of spraying room: more paint spraying workpeces, less paint to spraying tools, ground, walls and filter screen, reduce the manitenance costs of spraying room, for the operator to create a clean working environment. Protecting the environment: high transfer efficiency makes the noon coating consume less, reduces the VOC volatilization which is harmful to the atmospheric zone layer, and better protects our environment.

|

|

|

|

|